It's the first nice day of summer; you've taken the convertible out of winter storage and you're ready to hit the road. The stereo is cranking sweet guitar riffs as you cruise the beach, but for some reason the feedback on Wayne Kramer's ax (Motor City 5, for the uninitiated) starts to sound more like the drone string on Ravi Shankar's sitar. And that's not good. Changing tracks, you find that same droning noise, and it isn't coming from your high-end stereo—in fact, it's your brakes. They are squealing. By the time you get back home, the noise has become so shrill it makes the dog hide under the porch and bark. The brakes seem to work just fine, but any application of pedal immediately makes the noise louder. Owww, it's hurting your ears. Time to check the brakes.

It's Music, Man

Let's make one thing clear right up front: Sometimes your brakes will make noise. If you expect supreme silence, or expect your mechanic to make your brakes totally mute in every circumstance—that just may not be possible. Relax, don't worry. A squeaking brake can stop a vehicle as quickly as a quiet one.

So what makes the squeal, then? Modern brakes use a cast-iron disc squeezed between two brake pads lined with friction material. Under the right conditions, the disc, the pads and the caliper they're mounted in can start to vibrate—in exactly the same way a violin's string vibrates when stroked by the horsehairs on the bow. The violin's pitch is controlled by the position of the violinist's finger on the string, not by how hard or fast the bow is stroked. Similarly, most brake squeals occur at a single discrete frequency. The speed of the vehicle and how hard you press down on the left pedal will only change the volume of noise, because the pitch is controlled by the stiffness and mass of the pad and disc.

Inadequate development at the manufacturer that leaves brake systems prone to noise can usually be overcome by a Saturday mechanic without totally re-engineering the caliper/mount/pad/disc system. We can try to damp out the noise, or simply change the resonant frequency of the whole arrangement until it stops singing in any audible frequency. Here's how.

Normal Pad Noises

Many brake pad compositions will make a swishing or grinding noise for the first few stops in the morning until the pads warm up and drive off any moisture they've accumulated overnight. Ever notice a hissing or grinding noise on some rainy or dewy mornings? It's the pads sweeping a thin film of rust that's formed on the iron discs, and it's perfectly normal.

In the past, brake pad friction material relied heavily on asbestos. Unfortunately, asbestos tended to give asbestos workers and brake mechanics lung cancer, so the industry has almost completely changed over to less dangerous alternatives. Kevlar is one material that's seen a lot of use, but it tends to be dusty. Improved brake performance is more important nowadays because of increased safety requirements and equipment—and the extra road-hugging weight that comes along with these. That leads to the increased use of metallics and ceramics in the brake pad friction material. And this stuff can make the brakes hiss or even grind a little as you slow down. It's a small price to pay for increased performance. So all pad noise is fine, right? Hold up there, Sparky, there's one brake noise you need to pay attention to right away. Many brake pads have a small finger of spring steel that will scrape on the disc as the pad reaches its wear limit. This tells you that it's time to change pads for fresh, thicker ones before the friction material wears completely away, and you're trying to slow down on the metal backing plates. It's a sound not easily confused with brake squeal—it's more of a ripping-sheet-metal noise, not a single, high-pitched note.

Silence, Please

Okay, let's dig in and silence our brake noise. One fix is to simply change pads to a different type of friction material. It's usually hard to beat the original-equipment pads for a good compromise of pad life, noise, grip, dust creation and price, but changing to an aftermarket premium metallic or ceramic pad just might change the interaction that affects the resonant frequency of the pad and disc and, literally, change its tune.

Go into any auto parts store and you'll see a shelf full of potions and widgets claiming to cure squeaks. One class of products I'm leery of is simple aerosols that you spray onto the pad's friction material. I have no idea if they actually make the squeak go away, because I'm unwilling to try anything that changes the friction characteristics of the pad. Let's not forget, the first reason your brake system exists is, in fact, to make your car slow down. Anything that could reduce that system's effectiveness in any way is probably not a good idea.

Still got noise? Or still have plenty of pad material remaining and don't want to drop fifty or a hundred bucks on a fresh set? You may be able to decouple the piston acoustically from the pad by purchasing shims made of Teflon, which are intended to go between the pad and the caliper's hydraulic piston. I've tried those shims with middling success—sometimes they work and sometimes they don't. Warning: Some calipers will not have enough extra travel in the piston bore to allow any shimming without making the brakes drag, at least with fresh, unworn pads.

You can achieve a similar decoupling without Teflon shims by simply coating the back face of the pad's backing plates with high-temp brake grease or even antiseize compound. Unlike shims, this tweak won't last forever, as water and road dirt will wash it away eventually.

A Sticky Solution

Our favorite tweak for squeaks relies on a different principle: Instead of using shims or lubricants to decouple the pad from the caliper, stick the backing plate to the piston or caliper housing, effectively making its mass far larger. That will move the system's resonant frequency out of the range that squeals. A smear of Super Glue won't do it: You need something that will withstand the water, salt, filth and especially the heat that cars see in hard everyday use. How hot do brake systems get? I've seen brake discs glowing bright orange at the bottom of Pikes Peak, and flames shooting out of the brake drums of trucks descending Donner Pass. I've seen the brakes on my own race car visibly glow right after a few hot laps.

I've used several products over the years, but they're all basically anaerobic adhesives, applied as either a lipstick-style film or a toothpaste-style goo. The application of this product is simple: Remove and clean up the old pads, or use new pads. Clean the area on the piston and caliper where the pad backing plate touches. Apply the antisqueal adhesive, reinstall the pads and button up. These anaerobic products will stay gummy until you apply the brakes and squeeze out the oxygen. Then they stick like, well, glue.

Whenever you're installing any brake parts, be sure you remove any corrosion or road dirt from the mating parts—the brake pad or caliper housing needs to be able to slide in and out to compensate for wear. Clean up any sliding parts, which may require a wire brush or a file, until you can push the pads in and out with your bare hands. I prefer to replace any brake hardware (especially on drum brakes) that isn't in perfect condition—hey, it's cheap insurance. Apply a thin film of high-temp brake grease to any sliding surfaces. Obviously, avoid getting anything like grease or antiseize on the pad or disc, and clean any greasy handprints off the disc surface before you hang the wheel on too.

Brake Hardware Nitty Gritty

1. This is one product we've tried that usually works to bond brake pads to the caliper and reduce or eliminate squeal.

2. This sheet-metal finger is just long enough to contact the disc when the pads are mostly worn out. The noise is calculated to make you replace the pads.

3. Here are two different compositions of brake pads. The one on the left is the stock pad installed by the factory, with a high concentration of organic fibers and brass particles. The aftermarket pad uses less brass and more ceramics for longer wear and improved braking

4. When installing new or old pads, sparingly coat all of the sliding surfaces on the pads, pins and hardware with high-temp brake grease. Use sparingly, and—duh—don't get any on the pads or discs.

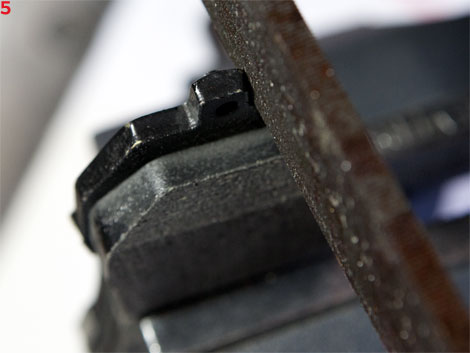

5. File, sandpaper or grind any burrs, extra paint, rust or high spots off the pads, new or old, to be sure the pad will slide easily in and out as the brakes are applied and released.

6. Check out the raised areas—leftovers from the manufacturing process. We had to file down the steel backing plate on this aftermarket pad.